Mtsc solutions are known for providing the fabric and textile industries with automated optical inspection solutions and systems. One of the most significant advantages this system offers is the consistency of operation according to the speed at which it can operate. With the help of this automated optical inspection system, a user will be able to get access to the inspection of data at any time of the production cycle to minimise waste, customer rejection, and cost and play a vital role in lowering the overall defect rates of the production system. Mtsc solutions are one of the leading automated optical inspection systems in Malaysia that offers a wide range of machine vision processes that increase accuracy and play a vital role in improving quality throughout the production line.

Helpful in defect detection automatically

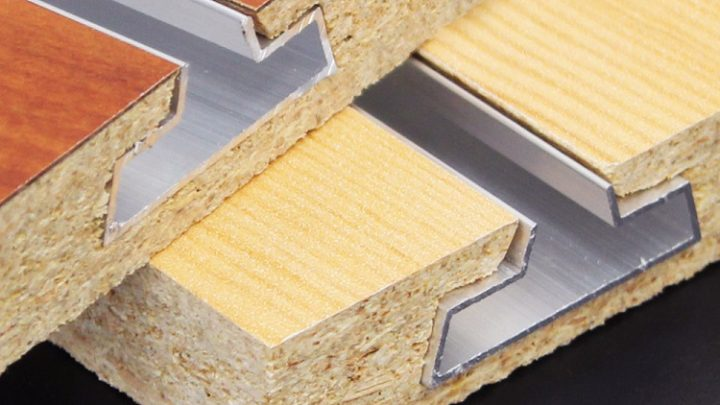

This automated optical inspection system plays a vital role in detecting the defects that may occur in any part of the production line quickly and conveniently. This optical inspection system is designed so that it will be able to detect any defect present in the textile. It will be able to tackle the defect finding task by looking at the different features present in the fabric, and if it differs from the regular demanding features, it will be able to detect the defect.

A large number of the algorithm has been run by the automatic optical inspection system similar initially at a very high speed. The main aim is to target important features like horizontal, vertical or diagonal, straight or curved lines, and other spot and area defects in the production line as a large number of the algorithm to run simultaneous Lee which can cover the textile defect and optimally combined with the specialised lighting planes. Various algorithms are designed in such a way so that it will be able to find the flaw in the fabric of the textiles. With the help of defect component inspection Malaysia, many defects present in the material may be detected by the system and also due to the advanced technology, it will be able to place the label on the fabric age automatically with the defect as well as it was also able to record the images of each detector the position of the defect which for the help the manufacturer to make the necessary changes in the fabric to make it desirable.

There is a possibility that more defects may be seen in one plane of view, but the system has been combined in such a way as to produce the report by inspecting the correct number of defects to be present in the fabric. Some of the defects that can be detected include colour variation, black spot, broken pick, contamination, dirty marks and many more. With the help of the detectable defect grading, the manufacturer will maintain the quality of the textiles and remain competitive in the market.