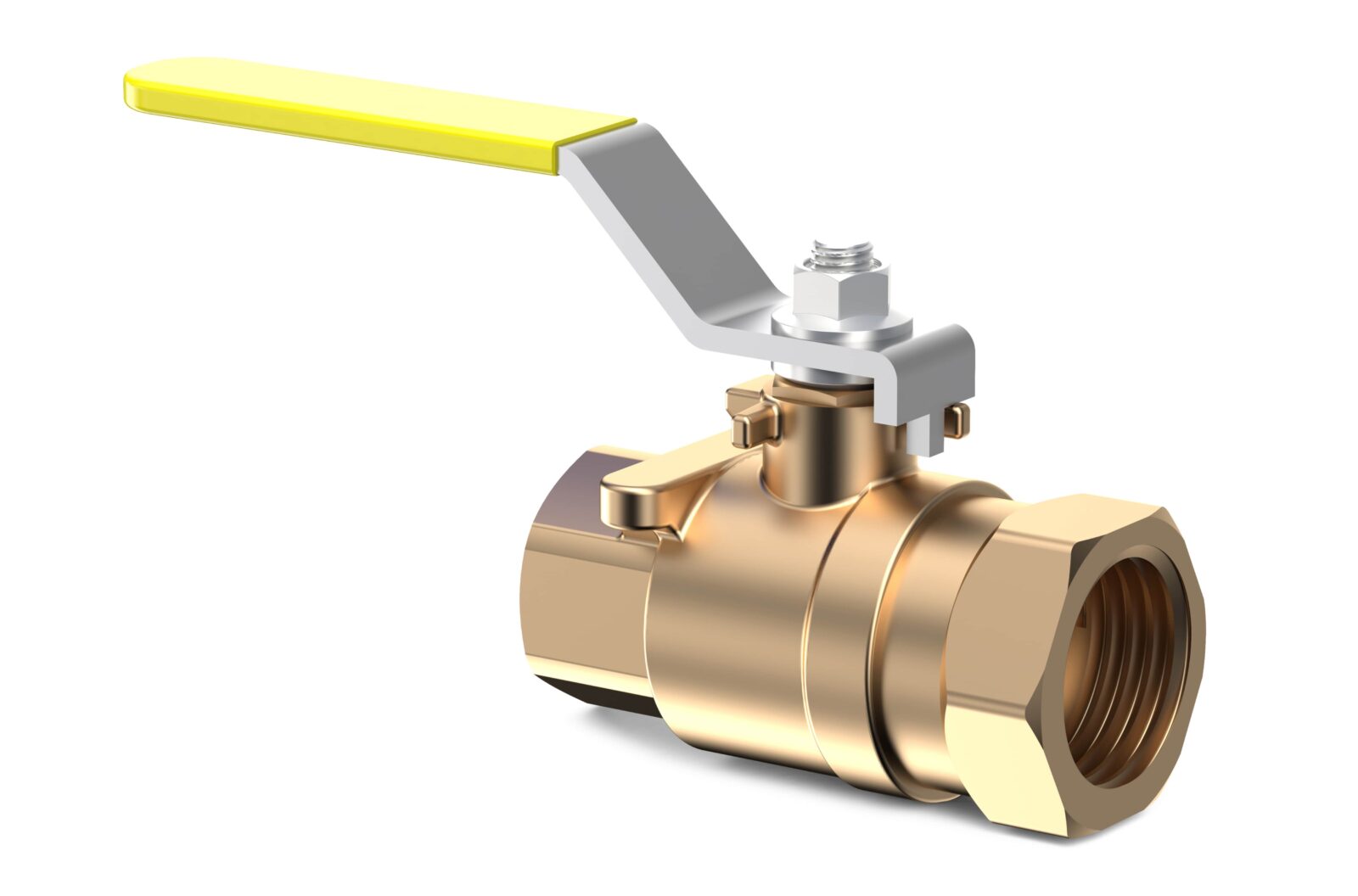

Since their inception in the 1950s, ball valves have been steadily gaining popularity across a diverse range of industrial applications ever since their introduction. The name of the valve originates from the ball with holes punched in it and housed within a metal casing. When the valves in Australia are activated, the perforation in the pipeline is brought into alignment with the output, which makes it possible for liquids, slurries, gases, and other media to pass through it. Manufacturers in Australia are responsible for producing some of the world’s most technologically sophisticated and secure industrial valves, such as the Australian Flocontrol Valve and Automation. When it is turned off, the ball will turn, which will cause the flow to be stopped. Because the mechanism is straightforward, ball valves can endure fluid flow very high in volume, temperature, and pressure. Compared to other kinds of valves, ball valves have a relatively small number of problems, which are outweighed by their many benefits. Slurries are one kind of medium that ball valve manufacturers do not advocate using ball valves for because of the heavy and gummy nature of the medium. They are not advised for use in continuous throttle applications either.

The Benefits Of Using Ball Valves

There is a vast selection of size and measurement options for ball valves. Some manufacturers even colour-code them so that you may identify them according to the application they are used for. You may purchase ball valves ranging from 0.5 to 121 centimetres on the market. The use of ball valves is strongly recommended for several reasons:

Durability

Ball valves are popular for their ability to continue functioning even when routine maintenance is required. Ball valves made of plastic outlast the metal ones regarding durability. Plastic ball valves do not experience rust or corrosion like their metal counterparts.

Simple Maintenance Requirements

Ball valves are relatively low maintenance compared to other types of valves. A single valve may continue to work for many years if the circumstances are proper. As a result of the constant need for ball valves, it is not very expensive to have repairs done, and replacements are readily accessible.

Mechanism That Is Simple To Operate

The ball valve design makes the installation process and any necessary repairs simple. Because of the ingenious design, the operation is simple, and there is no need to be concerned about side loads, which often cause issues with butterfly valves.

Efficiency

Applications that need a regulated flow often choose ball valves as their primary source of flow regulation. Because they are completely watertight and can open and shut in the blink of an eye, they are an excellent option for crisis management.

Access And Affordability

Due to the widespread use and growing demand for ball valves, several manufacturers are present worldwide. These manufacturers develop, produce, and provide various sizes and dimensions of valves.

Safety

Ball valves of good quality are reliable, even when subjected to high pressure and temperatures in the flow they regulate. They provide a risk-free service despite the harsh circumstances of the industrial environment.

Conclusion

The design of the valves in Australia is so adaptable that they may be used for various purposes, ranging from simple home applications to intricate workplace procedures. The fact that they may be designed in various ways makes them an economical option. Ball valves are an excellent purchase since they are long-lasting and continue to perform their intended purpose for a significant time.